Restoring the Buckingham Palace Turret Clock

Read about the restoration of the Buckingham Palace turret clock

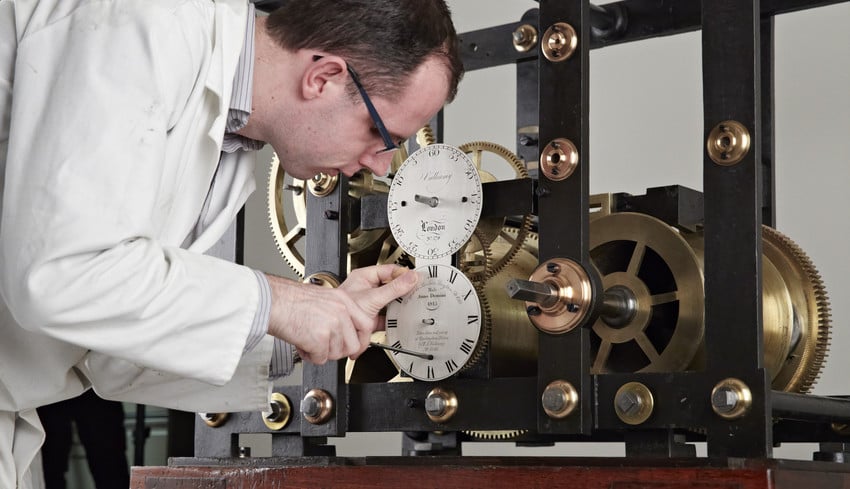

The movement

The bearing and acting surfaces of the movement were all in acceptable condition and required little attention.

The cast-iron plates, pillars, brackets and cocks of the movement were finished in a dark brown paint, although on some parts a darker paint (possibly applied during a previous restoration) was also present. After carefully removing and cleaning all of the old oil and dust with spirit solution, the cast iron components were treated with a microcrystalline wax for protection.

The bronze and brass components of the clocks movement had previously been finished with a shellac-based lacquer, however much of this lacquer had broken down over time resulting in large areas of oxidation. It was decided to remove all remaining lacquer with an alcohol solution, before removing the oxidation with a solution of diethylene triamine pentaacetic acid (DTPA), of approximately pH 10. Finally these were then re-lacquered with a cellulose lacquer.

Some of the bronze and brass components also had painted steel parts attached that could not be removed. These steel parts had a black oil-based paint applied and in these instance the DTPA solution was mixed with Sodium Carboxymethyl Cellulose (SCMC) to form a paste that was then applied to localised areas of oxidation.

The steel components within the movement showed no major signs of oxidation.

Any steel parts not painted or attached to brass/bronze components were treated in a proprietary spirit-based horological cleaner prior to rinsing in a spirit rinse, any screws which had evidence of having been blued were re-blued prior to being treated in oil.

The movement and case was fully assembled and photographed in the horological conservation workshop prior to being dismantled for transportation and assembly in the clock loft.